Hardwax oil is a proven and practical coating for residential and commercial use. Already well-established in Europe, this all-natural wax oil is steadily gaining traction in America. Beautiful and fumeless, hardwax oil is a finish of the future.

Yet polyurethane is the go-to for contractors thanks to it’s a durable, protective coating that works like a thin coat of armor for your floor. Water-based polyurethane is a ‘set it and forget it’ type of finish, with the top products providing 10+ years of easy, long-lasting protection.

While hardwax oil also provides excellent protection for your floors, you must maintain it throughout the years, reapplying it whenever you notice signs of wear.

In this article, we’ll compare hardwax oil vs polyurethane vs hardwood floor wax to help you decide the best option for your home or commercial setting.

Types of Hardwood Floor Finishes

Choose between hardwax oil, polyurethane, or hardwood floor wax to protect your hardwood floors. Learn more about the types of hardwood floor finishes available.

Hardwax Oil

Hardwax oil is a natural oil that deeply penetrates the wood fibers in hardwood flooring to create a seamless, durable finish.

As a film-forming finish, it creates a subtle protective layer (or ‘film’) on the surface of the wood. This enhances the appearance of hardwood by bringing the grain to the surface, while also creating a protective barrier against moisture and scratches.

Hardwax oil comes in single or two-component formulas. The best option is a two-component product. This comes with an isocyanate hardener that speeds up drying and increases durability. Single-component hardwax oil takes longer to dry and isn’t as resilient.

Polyurethane

Polyurethane is a synthetic resin finish that, when applied to hardwood floors, creates a visible protective layer on top of the wood.

Unlike hardwax oil, polyurethane sits on the surface of the wood rather than absorbing into the wood fibers. This protects hardwood flooring from scratches, chemical spills, and water.

As one of the most durable types of floor finish, polyurethane is the go-to option for most contractors and homeowners. It can last over 10 years, depending on how much you walk on the floors.

It’s also one of the easiest floors to maintain. Spillages (even harsh chemicals) can simply be wiped away without affecting the beauty of the finish. Explore our best polyurethanes for hardwood floors.

Hardwood Floor Wax

Hardwood floor wax (also known as wood wax paste) is a solvent wax finish designed for hardwood flooring that’s primarily used in historic homes. While it can still be found in stores today, it isn’t a modern choice of finish because it’s not practical.

The protective layer it offers is weak – particularly when compared to hardwax oil or polyurethane – and therefore doesn’t last long. It wears away quickly, so it’s unsuitable for high-traffic areas (unless you’re prepared to reapply the wax regularly).

Additionally, hardwood floor wax has a high VOC content, which means it emits chemicals and produces strong odors as the finish dries. This isn’t ideal for eco-conscious homeowners or contractors.

Benefits of Hardwax Oil For Hardwood Flooring

Hardwax oil is one of the best choices of finish for hardwood flooring (alongside polyurethane). It’s easy to apply, repair, and maintain – with a range of customization options available. Learn more about the benefits of hardwax oil for hardwood below.

Easy application

Application is quicker and more DIY-friendly compared to other hardwood flooring finishes (like polyurethane and hardwood floor wax). Generally, you only need to apply two coats for a solid finish, but it’s important to check and follow the manufacturing guidelines for flooring. Hardwax oil also shouldn’t abrade in between coats, making it easy for DIY-ers.

Easy repairs

Hardwax oil can be patch-repaired. If scratches or signs of wear appear in a particular spot, you can touch up the area without refinishing the entire floor. The formula dries fast, so furniture can quickly be moved back into place after repairing. This makes it an ideal flooring for restaurants, as floors can be touched up after closing without disrupting business the next day.

Minimal maintenance

Hardwood flooring finished with hardwax oil requires minimal maintenance, but how often you need to reapply the wax depends on how heavy the foot traffic is.

Essentially, the more you walk on the floors, the more frequently you’ll need to reapply a hardwax oil finish. For this reason, hardwax oil may not work well in heavy commercial areas (polyurethane is best for this), but it’s ideal for a restaurant or home.

Waxed floors should be cleaned with a special wax floor cleaner. These contain a small amount of wax, so as you clean the floors, you strengthen the finish, which prolongs its lifespan.

Durable/cost-effective

Hardwax oil is durable and long-lasting, making it a good investment for hardwood flooring and a cost-effective option long-term. Since you can easily repair blemishes and worn areas, this can reduce the need for frequent refinishing.

Customization

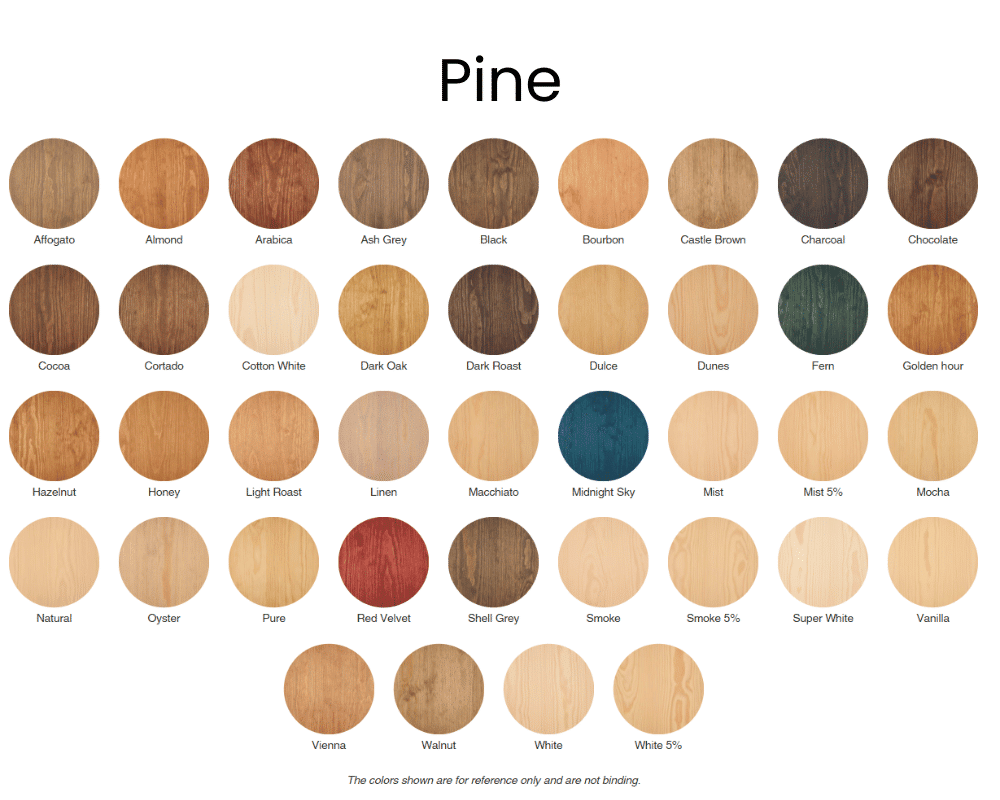

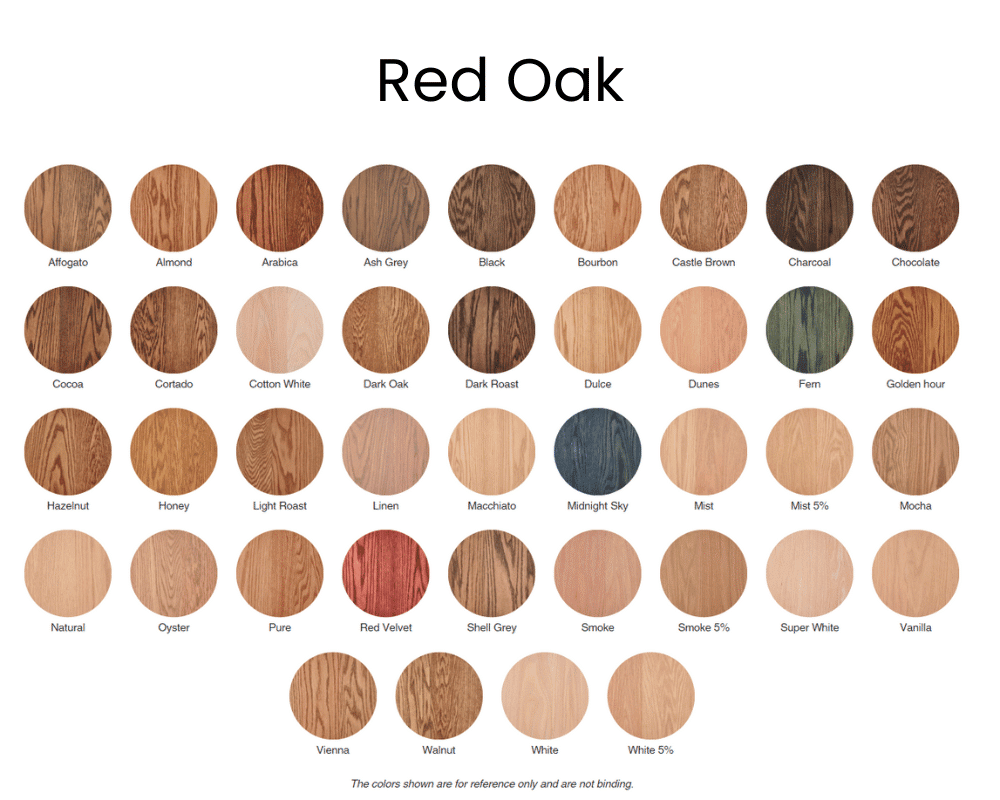

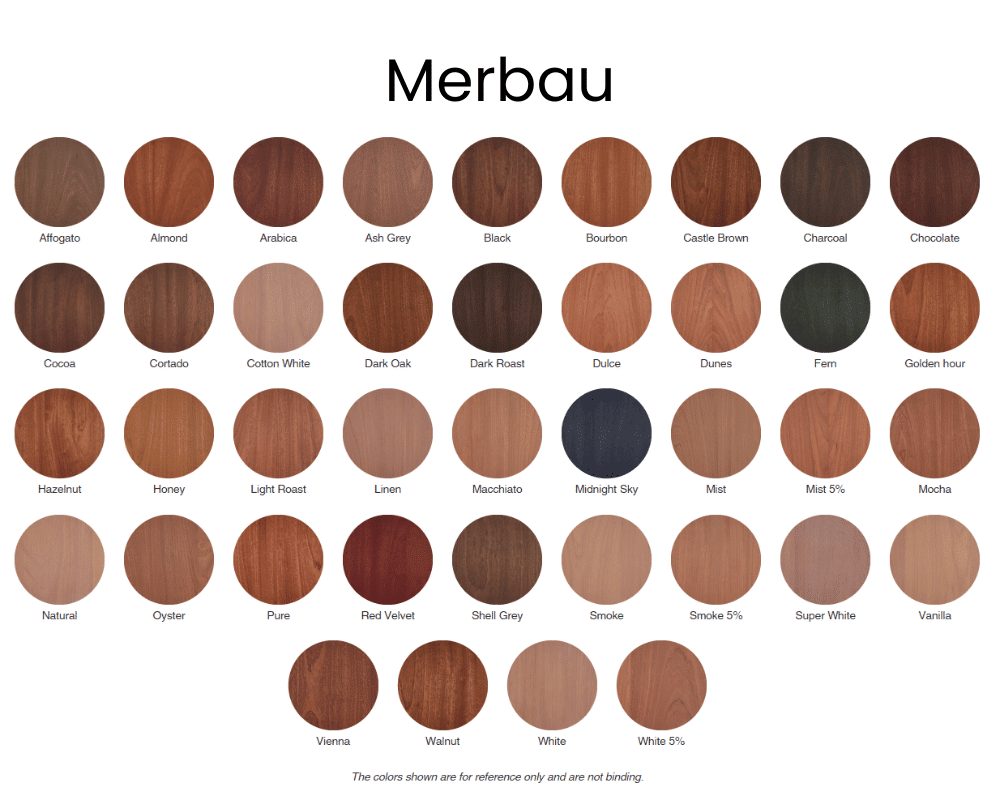

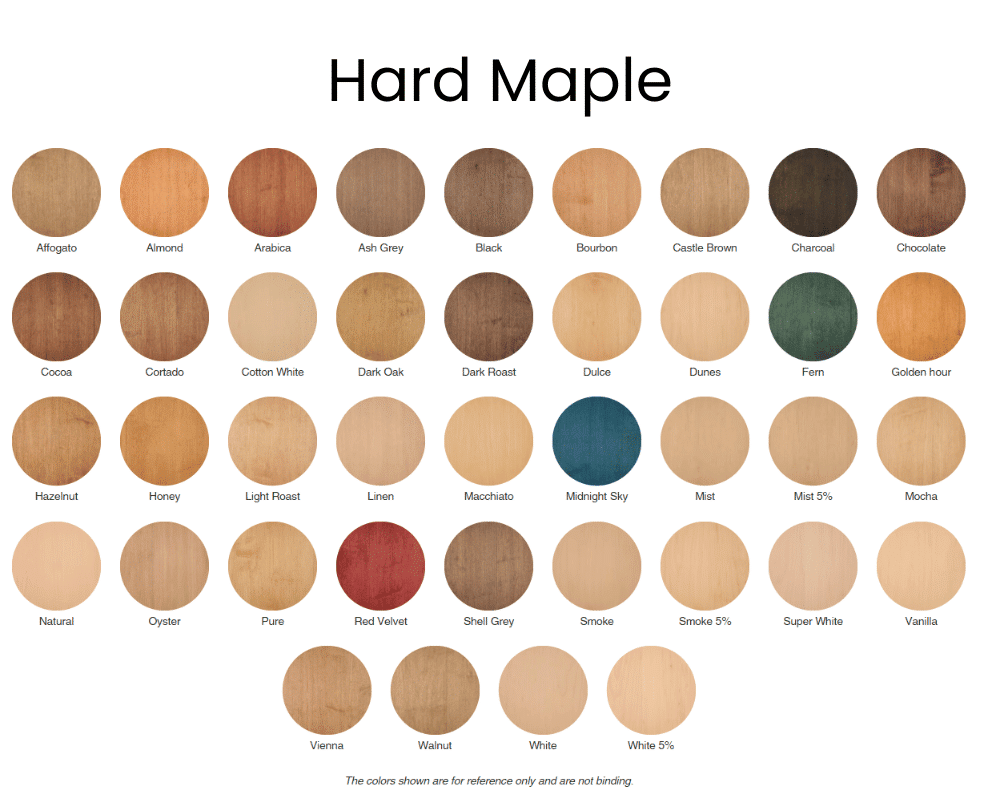

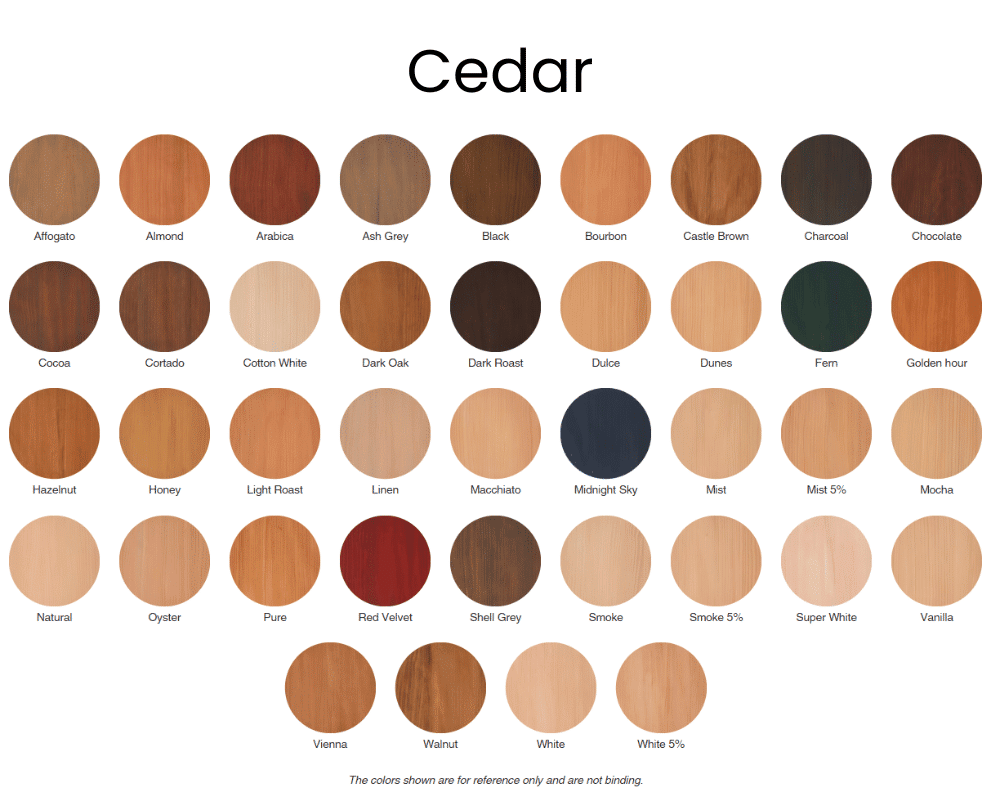

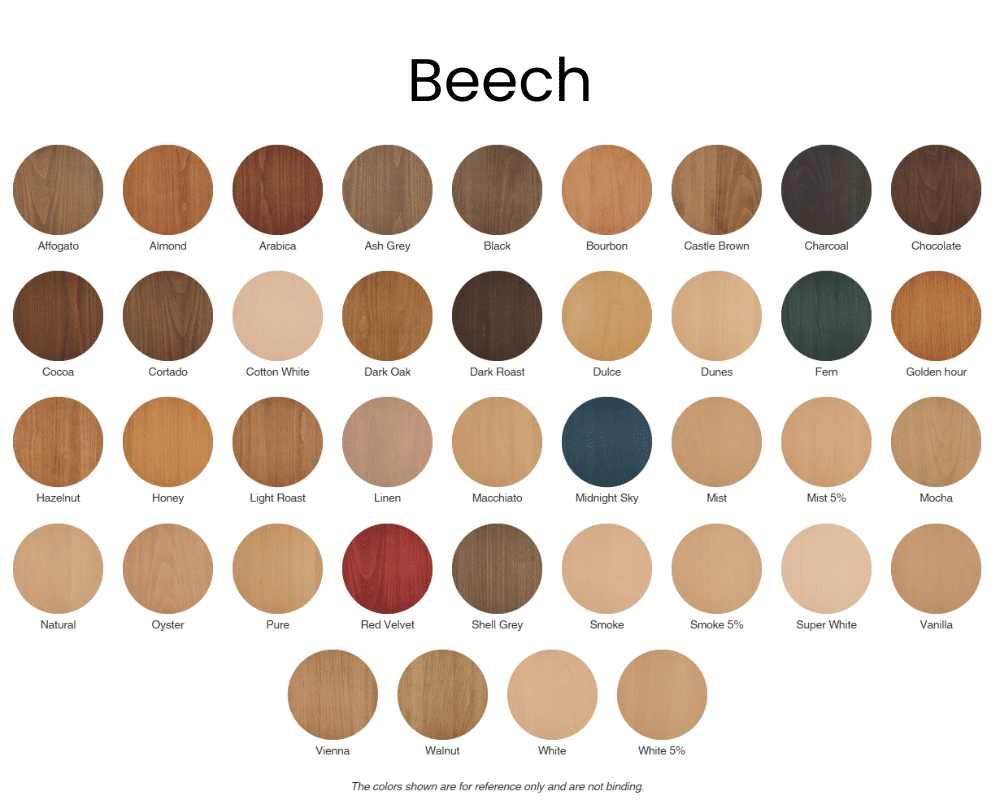

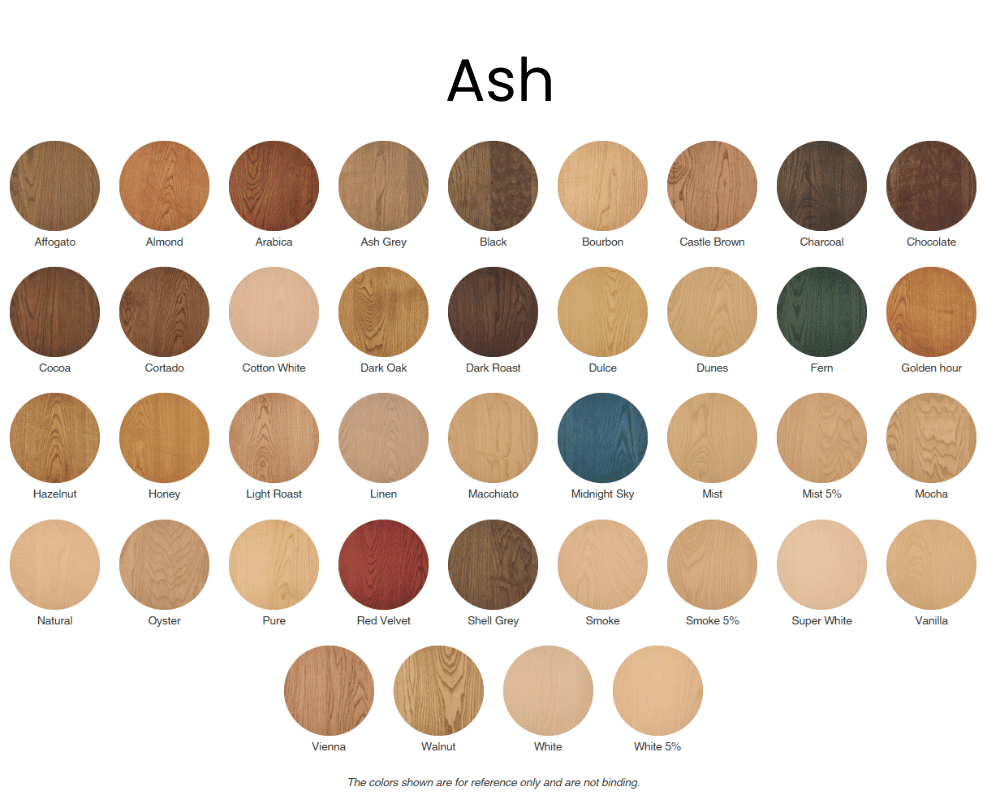

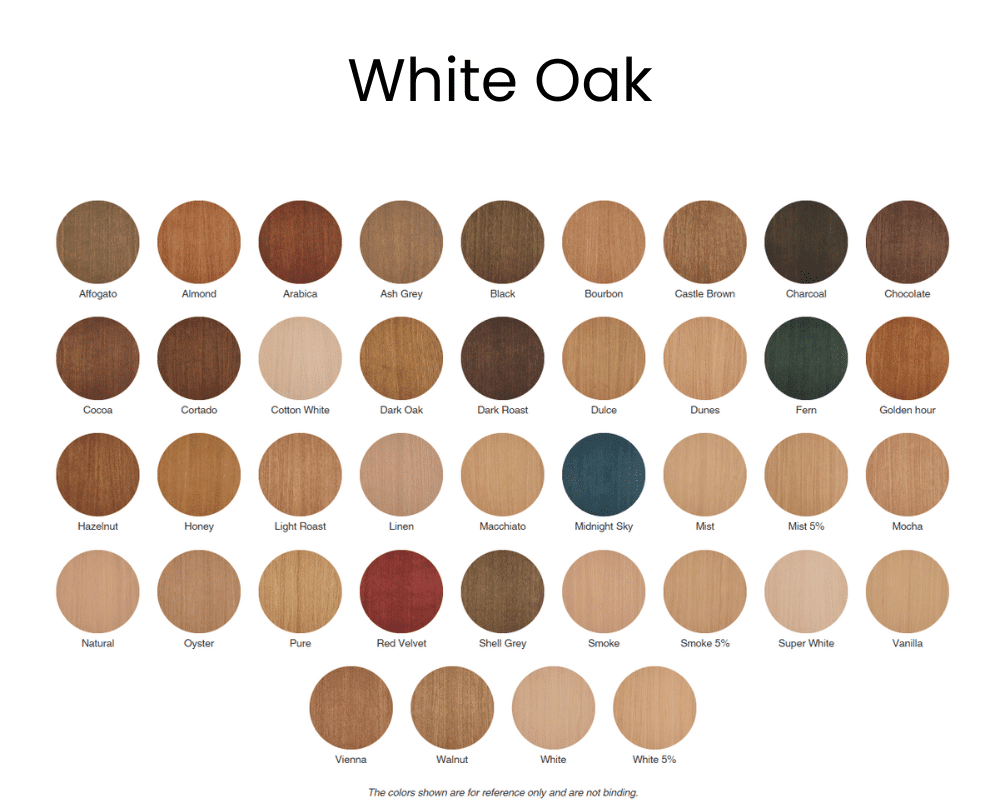

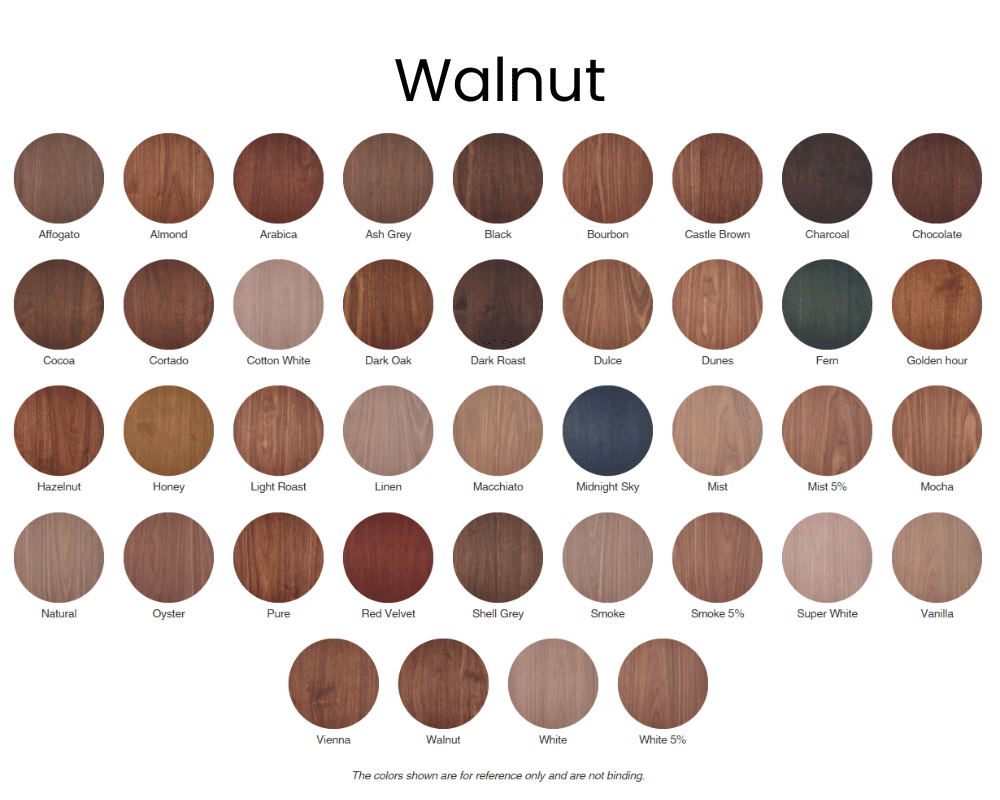

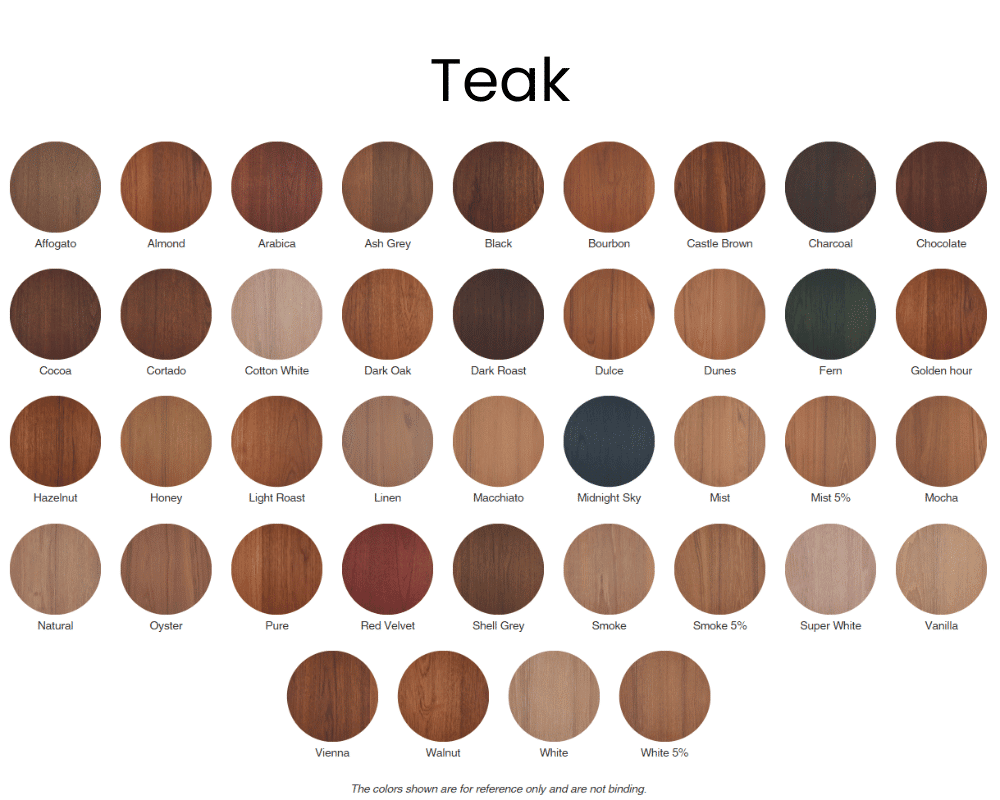

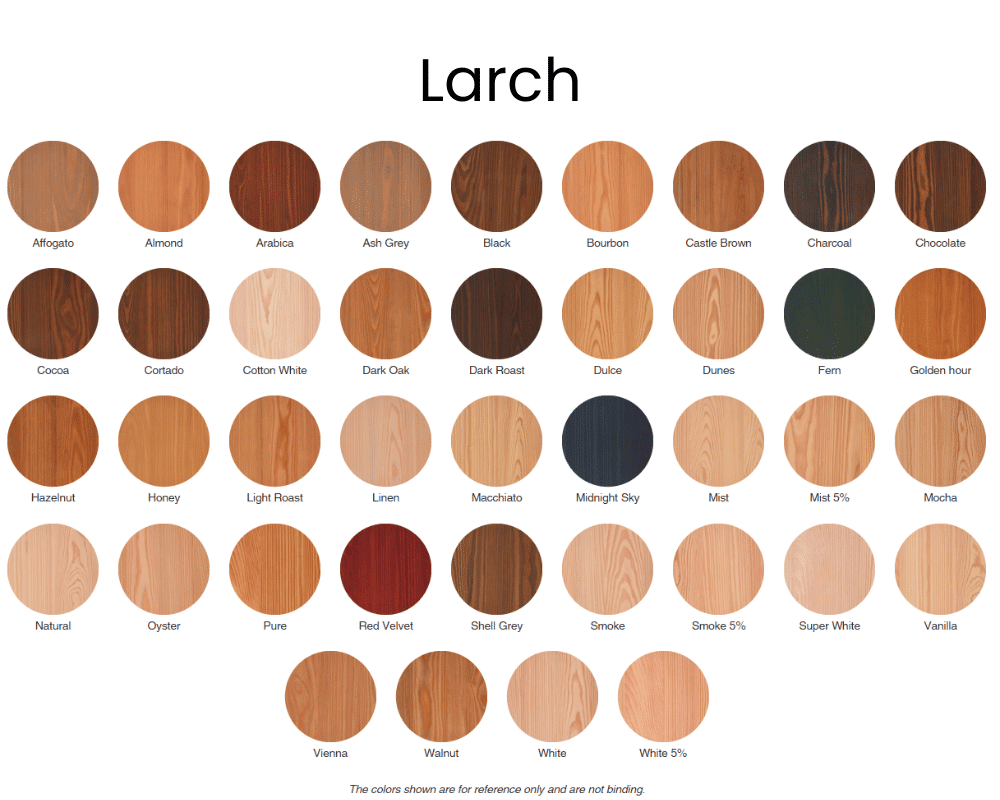

Hardwax oils come in a range of sheens – including ultra-matte, matte, or satin sheen – and a wide selection of natural colors. Popular hardwood floor colors include walnut, cotton white, cherry, ash gray, charcoal, mahogany, and smoked oak.

Comparing Hardwax Oil Vs. Polyurethane

Hardwax oil has its benefits compared to polyurethane, namely its low VOC content that makes it less toxic to inhale. Yet there are benefits to polyurethane vs hardwax oil, including a higher stain resistance, easy spot repair, and wider range of sheens.

Good durability

With proper care and periodic spot repair, hardwax oil can outlast a polyurethane-coated floor. You can reapply it to remove scratches, scuffs, and general wear. Over time, poly surfaces will show signs of wear and (since you can’t patch-repair polyurethane), you need to refinish the entire floor to fix blemishes.

However, hardwax oil has a lower chemical resistance compared to polyurethane. For example, spilling bleach on a hard-waxed floor will leave a dark stain, which requires patch-repairing to fix. Yet spilling bleach on a polyurethane floor can simply be wiped away.

Ultimately, both hardwax oil vs polyurethane are durable choices. But hardwax oil is only better if you’re willing to maintain it properly with regular spot repairs.

More eco-friendly

Hardwax oil has the lowest VOC content of any other type of finish – including polyurethane or hardwood floor wax. Therefore, it’s the safest, most eco-friendly, and least toxic flooring on the market today. This can make it preferable for contractors to work with frequently.

Limited sheens

Hardwax oil seeps into the wood fibers after application. This is unlike polyurethane, which sits on the wood surface. This means you are limited to an ultra-matte, matte, or satin sheen finish when using hardwax oil.

Whereas polyurethane comes in a variety of sheens and can therefore be applied to create a shiny finish on hardwood floors.

Comparing Hardwax Oil vs Hardwood Floor Wax

Hardwood floor wax is – essentially – an outdated product in the 21st century. The only time contractors apply it is to maintain historical accuracy of homes from long ago. Hardwax oil is the modern solution as it provides more durability, flexibility, and ease of maintenance to homeowners and businesses.

Less maintenance

Hardwax oil requires significantly less maintenance compared to hardwood floor wax. It’s recommended that paste-wax floors (using hardwood floor wax) are refinished every 2-3 months to cover fading, which can be cumbersome.

Whereas hardwax oil soaks into the wood fibers, creating a durable, long-lasting finish that requires refinishing every 2-3 years, depending on how much traffic the floor receives.

Easy application

Hardwax oil is considered the technologically advanced version of hardwood floor wax. In simple terms, hardwood floor wax has been liquefied and combined with other strong solvents to create hardwax oil.

The newer, improved solution (hardwax oil) is therefore easier to apply compared to hardwood floor wax (read our application tutorial below).

Best Hardwax Oil Finish

When choosing a hardwax oil finish, you will want to select a product with long-lasting qualities. Our best hardwax oil finishes include Bona Craft Oil 2K (which is a naturally penetrating oil that doesn’t contain wax) and Rubio Oil Plus 2C. These both provide long-term performance on our hardwood floors.

Rubio Monocoat Oil Plus 2C

Rubio Monocoat Oil Plus 2C is a 2-component hardwax oil that adds a beautiful color while protecting hardwood in a single coat.

This eco-friendly, 0 VOC formula is simple to mix and spread, so it’s easy to work with, which means it’s a favorite of DIY-ers..

With 55 different colors available – including oak, pine, touch of gold, and silver gray – this hardwax oil produces surprisingly long-term durability with significantly less effort.

Bona Craft Oil 2K (Wood Floor Finish)

Bona Craft Oil 2K is a low-odor, fast-drying, natural penetrating oil derived from vegetables and catalyzed with a hardener, it gives your hardwood floor incredible performance and a beautiful look.

This formula works well with many wood species, especially cherry, beech, walnut, and smoked oak.

Choose from eight colors or blend them to create a unique color variation. To increase wear resistance, you can overcoat the surface with Bona Traffic HD.

How to Apply Hardwax Oil Finishes to Hardwood

Hardwax oil is one of the easiest and most pleasant types of hardwood finishes to work with. It’s easy to apply – with a similar application process to waxing a car – and has a clean smell.

Sanding before application

If you’re sanding hardwood floors before applying hardwax oil, follow our tips on how to sand hardwood floors. Sanding quality is crucial. Any digs, chatter, or other flaws in the flooring will stand out once you apply hardwax oil.

Small vs large areas

For small areas, you can apply hardwax oil by hand – rubbing it into the floor and wiping away the excess. In larger areas, we recommend using a buffing machine to apply it and work it into the floors.

Using a buffer machine

A buffer allows you to apply oil to hardwood quickly to create a soft, beautiful finish. Buffers require balance to deliver an even application, so make sure you find the balancing point on the machine to apply hardwax oil consistently.

Work in small sections

Hardwax oil dries quickly, so it’s best to work in small sections to get the perfect finish. When applying the finish by hand, wipe it onto a small area and buff it in before moving on to the next section. If using a buffer machine, start in a corner of the room and work your way across.

FAQs

How Long Does Hardwax Oil Last?

Hardwax oil can last a long time in low-traffic areas, as long as 2-3 years. In high-traffic areas, it may not last as long, but it all depends on how the hardwood looks over time. You can easily reapply the formula to hardwood floors without significant preparation, making it one of the most convenient types of finishes.

Is Hardwax Oil Good For Floors?

Hardwax oils are a modern finish, specifically designed to protect and beautify hardwood flooring. Because the oil penetrates the wood fibers, it creates a deep protection against moisture damage and general wear.

Alongside this, hardwax oil creates a subtle protective coating on the surface, which boosts scratch resistance. Because the protective film is so subtle, hardwax oil enhances the appearance of the grain, making hardwood look more natural.

How Do You Clean Hard Wax Oil Floors?

Begin by sweeping or vacuuming the floor regularly to remove dust, dirt, and debris as these particles can scratch the surface over time. For routine cleaning, use a pH-neutral wood floor cleaner specifically designed for hardwax oil finishes.

Dilute the cleaner in water according to the manufacturer’s instructions, ensuring that the solution is mild enough to preserve the oil’s protective layer. Mop the floor using a damp (not wet) microfiber mop, as excessive water can penetrate the wood and cause damage. For stubborn stains or marks, a specialized spot cleaner or a gentle scrubbing pad may be used carefully.

Periodic reapplication of maintenance oil is recommended to restore the luster and protection of the floor over time.

Is Polyurethane Good For Floors?

Polyurethane creates a strong protective coating on the surface of hardwood floors. This protects your floors against scratches and water spills. Contractors choose polyurethane for its proven durability in both commercial and residential settings.

While polyurethane comes in a variety of sheens and can make hardwood look shiny (compared to hardwax oil which only comes in matte-effects), the protective layer can slightly reduce the appearance of the natural grain.

Summary

Hardwax oils are one of the best hardwood floor finishes on the market today. As an easy-to-apply solution that requires minimal long-term maintenance, it’s highly suitable for DIY-ers and high-traffic areas (including commercial settings).

With deep penetrating qualities, hardwax oil brings out the natural aesthetic of the wood, unlike any other hardwood floor finish. The only disadvantage is the lower chemical resistance (meaning stains need patch-repairing) and the limits in terms of the glossy effects available.

Ready to finish your hardwood floors? Explore our collection of expert wood finishes the professionals trust.